Equipment

- Stencil Printer – Speedline MPM Momentum

- Pick and Place – Samsung SM421

- Reflow Oven – Vitronics XPM 520

- AOI – Mirtec MV-6 OMNI 3D AOI

- X-Ray – Glenbrook RTX-113 X-ray Inspection Station

- Selective Solder – RPS Rhythm Slide

- Board Cleaning – Aqueous Technologies, DI, Closed Loop

- Selective Coating – SCS Selective Coating Machine

- UV Curing Oven – Dymax 39080

- Lead Cutting/Forming Machine – LCW Automatic

- Hot Air Rework System – Pace ST-350

- In Circuit Test (ICT) – Checksum System

- IC Programming – Various Computers

- 3D Printing – Filament and Resin

- Potting – Mix/Measure/Dispense Equipment

- Test and Curing Ovens – Precision, Quincy Lab

- Magnification – Vision Engineering Matis, AmScope to 90x

- Lead Forming – GPD CF8, Novastar, Mancorp, Kingsing

- CNC Router – Baileigh WR-23

- Spray Equipment and Fume Hood

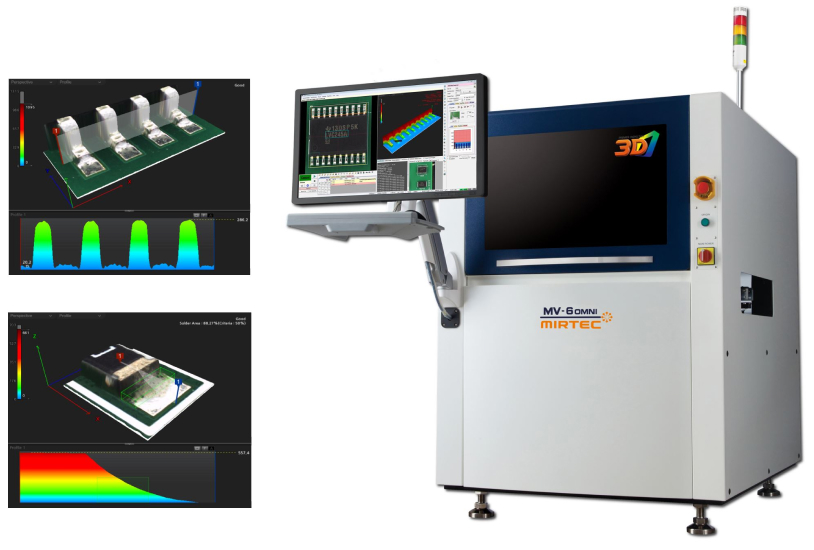

3D AOI – Mirtec MV-6 OMNI

- Exclusive 15MP/25MP CoaXPress Camera System

- OMNI-VISION® 3D Digital Tri-Frequency Moiré Technology

- Leading-Edge 12 Projection Blue DLP Technology

- Precision Compound Telecentric Camera Lens

- Eight Phase Color Lighting System

- 10MP/18MP SIDE-VIEWER® Camera System

- Programmable Z-Axis Multi-Focus System

- INTELLI-PRO® Automatic Programming Software

- Multi-Functional AOI-SPI Fusion Technology

- INTELLISYS® Industry 4.0 Intelligent Factory Automation System